ONE STEP Co.,Ltd.

Originally, at the time of establishment, the company aimed to open a Japanese language school in the Philippines and support job hunting in Japan. The company also tried a school in Negros Oriental province, Philippines for about 4 months.

We have been trying to find a business partner with financial support and match the businesses, however we have not been able to match the purpose and direction of our business with other companies. So, we gave up on this thought of reliance upon others and thought of taking this challenge again, after establishing our own profitable business. And consequently, we have decided to prioritize the Battery Solution Business.

The battery rechargeable charger is a technology, that only we have at present, which was completed by our developers over 30 years.

Business Content

Our company was founded in March 2017, and currently specializes in lead-acid batteries, especially large-scale lead-acid batteries, and we are conducting research and development, production of regenerators, and providing services using such regenerators.

(Currently, we are mainly developing support for forklifts and mobile phone base stations.)

Mission

Our mission is to contribute to the environment by reducing large-scale industrial waste using our technology.

We will engage in educational and instruction activities such as maintenance guidance to extend the life of batteries through seminars.

Business Status

Regarding the regeneration of Lead-acid batteries, there has been a battery regeneration industry in Japan for about 20 years using various regeneration technologies.

Unfortunately, we feel that there is no outstanding technology out there yet.

As with our company, we deal with second-hand goods.

Unlike new batteries, the deterioration status of each battery is totally different, depending on the purpose of use, usage status, usage environment, maintenance status, refurbished used battery, etc.

Therefore, it is impossible to regenerate all kinds of battery.

We are not in the stance of being able to do anything, but we propose recycling and the best cost reduction method according to the customer’s requirement while using our technology.

Our ultimate goal is to build a relationship of trust with who accept our proposal and eliminate together the non-renewable batteries.

ONE STEP’s New Technology

Explanation of Battery regeneration principle and technology

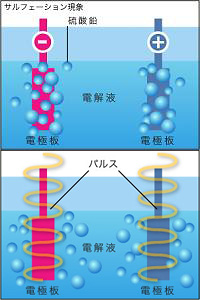

According to Dr. Cooper’s (USA) dissertation published in 2000, Lead-acid batteries have a resonance point at 2 to 6 MHz. Our battery regeneration method uses exactly this resonance phenomenon (tuning) (by using our original new technology of applying pulse voltage to the electrodes), and is the fastest and most efficient mechanism to remove sulfation and charge the electrode surface at the same time.

With this method, we were able to realize a dramatic regeneration speed (several days → several hours) compared to other companies’ regenerators and power saving as well as regeneration of extremely deteriorated (reduced to a voltage of several Volts, 100 times increased resistance value) products.

Summary

STRENGTHS

1) Regeneration machine is small and lightweigh→Regeneration work is possible on site

Currently, transportation to factories is a large cost for recycling batteries such as large-scale batteries.

・External dimensions: W35cm×H11.5cm×D29cm (H is 14.5 cm, when the rubber part on the bottom is added.)

・Weight: Approx. 8 kg

2) Reduction of Regeneration time

In the conventional regeneration method, the regeneration work that takes about 1 to 2 weeks for the entire process is basically done in one day at our company. Even a forklift can be completed in 3 to 5 hours.

3)The above makes it possible to regenerate at an overwhelmingly low cost.

4) Excellent results after refreshing

80% to 90% or more of the storage capacity (*) can be regenerated, almost to a state as new.

(*) The degree of regeneration varies depending on the deterioration state.

WEAKNESS

・Lack of experience and achievements

We have accumulated a lot of experience such as demonstrations, but we still need to accumulate experience and know-how of this technology and the usage of the regenerator on various used batteries.

Achievements (such as demonstrations)

DOMESTIC

Mobile Phone Base Station Battery: Major telecommunications carrier company

Forklift: Major logistics companies, major food manufacturers, and other medium-sized companies

Special vehicles: Major manufacturers, etc.

About 35 companies

OVERSEAS

Electric motorcycle (Vietnam), Trailer (Philippines), Passenger car (Hong Kong)

Future

Alternatives to Lead-acid batteries such as lithium batteries are appearing one after another, but there is no definitive alternative to Lead-acid batteries in terms of cost, and it seems that lead-acid batteries will not disappear for a while.

In addition to the forklifts and mobile phone base stations mentioned above, there are a wide variety of lead-acid batteries such as for solar power, ships, golf carts, and emergency batteries for buildings. We will respond while accumulating each experience.

Mass production is scheduled to start from January 2021, but with the start of mass production, we will work on research and development of the following technologies.

・ Regeneration device for small lithium battery

・ Solar lead battery

etc.